Hi, I am new to Seamly 2D. Thank you for accepting me into the forum.

I have a little problem here. After I made my patterns and pieces, as I try to layout, a “Couldn’t prepare data for creation layout” message popped out. Why did that happen? How do I make it work?

Here is my file.

shirt_dress.sm2d (62.0 KB)

1 Like

@Janae_Hung quote=“Janae_Hung, post:1, topic:14697”]

I have a little problem here. After I made my patterns and pieces, as I try to layout, a “Couldn’t prepare data for creation layout” message popped out. Why did that happen? How do I make it work?

[/quote]

Welcome @Janae_Hung

Often when this happens it’s because there’s something wrong with a curve’s control point(s) or a control point is at an angle that causes an error in calculating the layout piece’s seam allowance path.

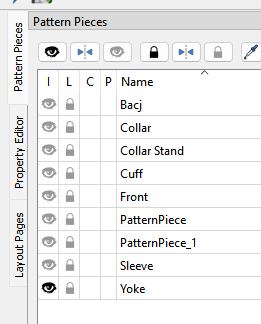

What I did is selected each piece one at a time and generated a new layout to find which piece was causing the error. Of course in this case it was the last piece in the list. - the Yoke.

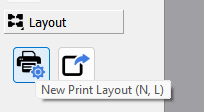

Use the New layout tool to create a new layout:

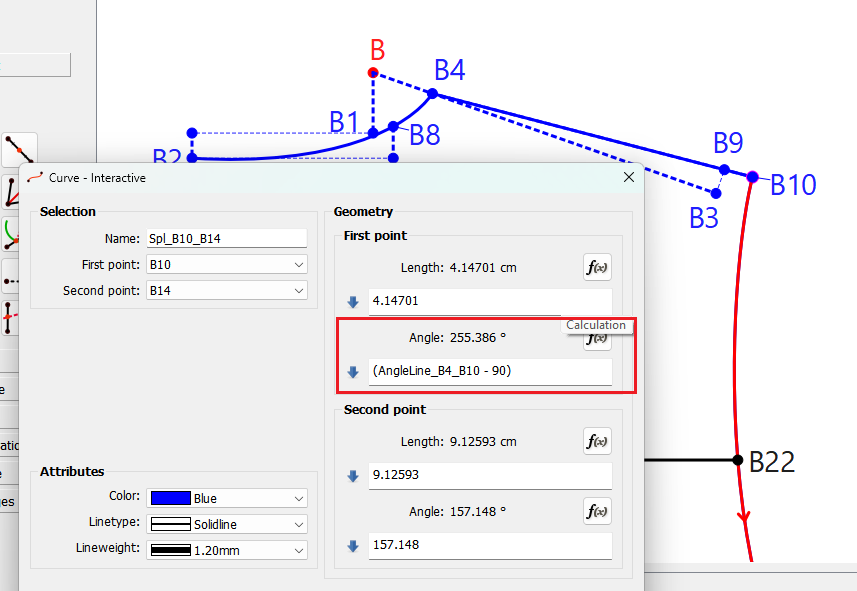

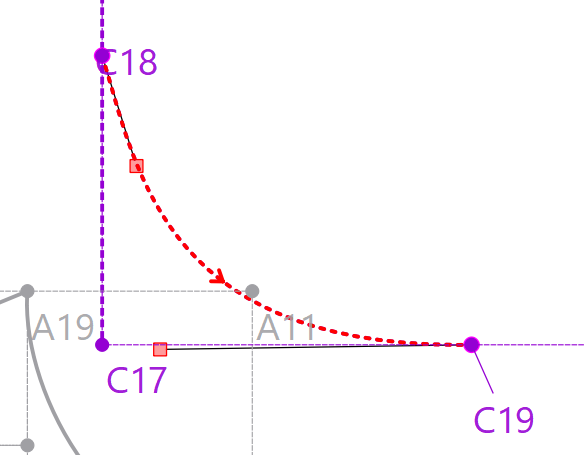

Once I found that it was the yoke causing the error I went back to Draft mode to see what may be the issue. One issue I found - which actually fixed the layout issue in the process - is that normally when you create a curve you want the start and end point control point angles to be perpendicular to the seam. In this the 1st control point for the Spl_B10_B14 should be perpendicualr to the Line_B4_B10. This will create smoother courves and no kinks across a seam.

So I added the formula to the CP1 angle:

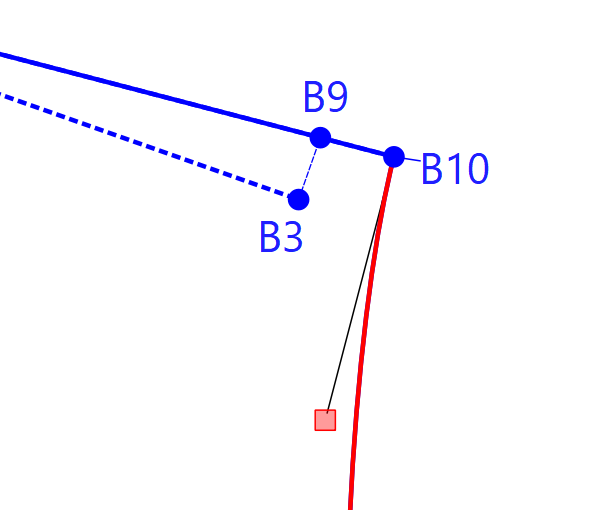

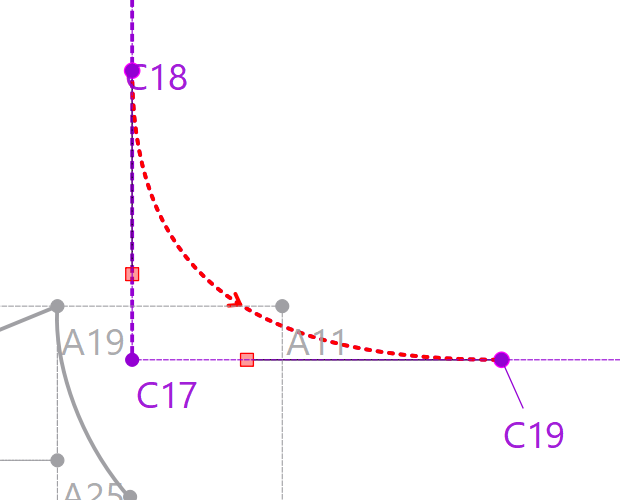

So now the control point is perpendiculatr toLine_B4_B10:

Just changing the angle was enough to fix the layout issue:

shirt_dress_fixed.sm2d (55.9 KB)

BTW. In the future please include any measurement file to make it easier for us to look at a pattern.

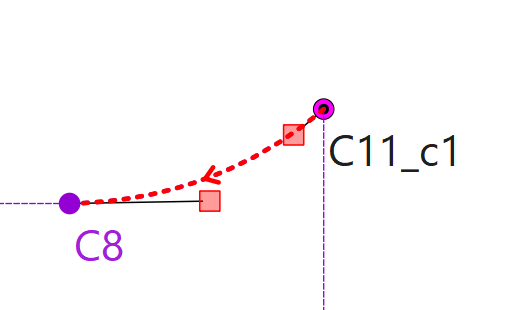

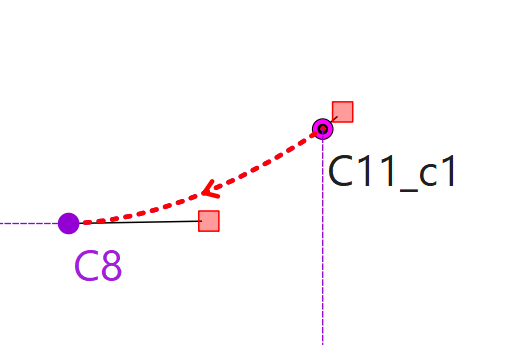

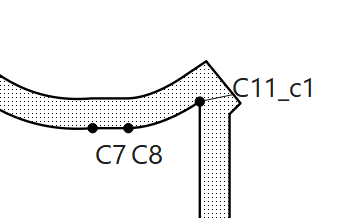

Also I suggest reading some of the topics on creating curves, and how to formulize the control points for smoother curves - especially for resizing patterns. For ex: I noticed the control points for the bottom corner curve on the front… where you want the CP angles to match the angle of the lines they blend into for a smooth transition:

This will cause kinks:

This will not.

2 Likes

Thank you so much. I checked and checked and couldn’t find the problem. So, it’s the angle of the start and end of a curve. This is the first time I had a problem like this. I now know how to fix it. Thanks again.

2 Likes

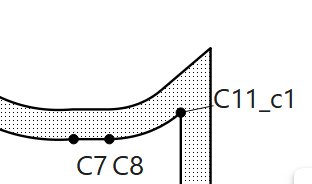

Yes. Often times when there an issue with pattern pieces or in this case the layout pieces it’s related to the curve control points. It’s why I always check the control points when there’s an iisue. For ex a common mistake is when a control point get’s flipped 180 deg…

This is fine:

This is not as the CP is flipped and is causing a loop:

In the case of your pattern and the layout it was math related, because we’re dealing with real numbers there’s rounding error. That’s where nudging the length or angle of a control point can be enough to fix the issue.

2 Likes

I have a lot of the cut-cornered seam allowance. I just thought it’s probably meant to be like that. Now, it makes more sense to me . CP is very important in trouble shooting. I will pay more attention next time. Thank you.

2 Likes