Some of you may be aware that my parntner (with his wife) and I have been in the costume business since 1981… and along the way we’ve done work that has popped up in some strange places. Back in the late 80’s, early 90’s we used to manufacter costumes for the halloween industry, and one of the things we used to make a was cheap Flapper dress with fringe. Well, later we found out that one of our customers (Junk for Joy) out in LA sold 4 of the dresses to the Bangles that were used in an MTV video with Little Richard. My partner just came across some pics online from the video. ![]()

You can never get enough fringes !

I love it ![]()

![]()

![]()

The funny thing is with the Bangle dresses… it looks like they never removed the chain stich that holds the bottom edge fringe in place. Without the chain it’s a royal pain to deal with. It was so long ago, but I think we later started shippping the dresses with the chain already removed. ![]()

Well the movie “Cabrini” that we (DC Theaticks) did some work on is soon about to hit the screens. The movie was mainly shot in Buffalo, NY.

We made 80 of the skirts and jackets for the orphan girls in about a 1/2 dozen sizes in 3 different colors of wool. Here’s what the jackets were like:

Here’s marking the top layer of a spread:

The weights you can see in the photo are weights from an old knitting machine we got when we bought a bunch of stuff when a friend that was closing a sports wear business. He used the machine to make the knitted cuffs for the jackets. The weights were used to keep tension on the knitting. Only once in 30 years or so did I drop one on my toes. ![]()

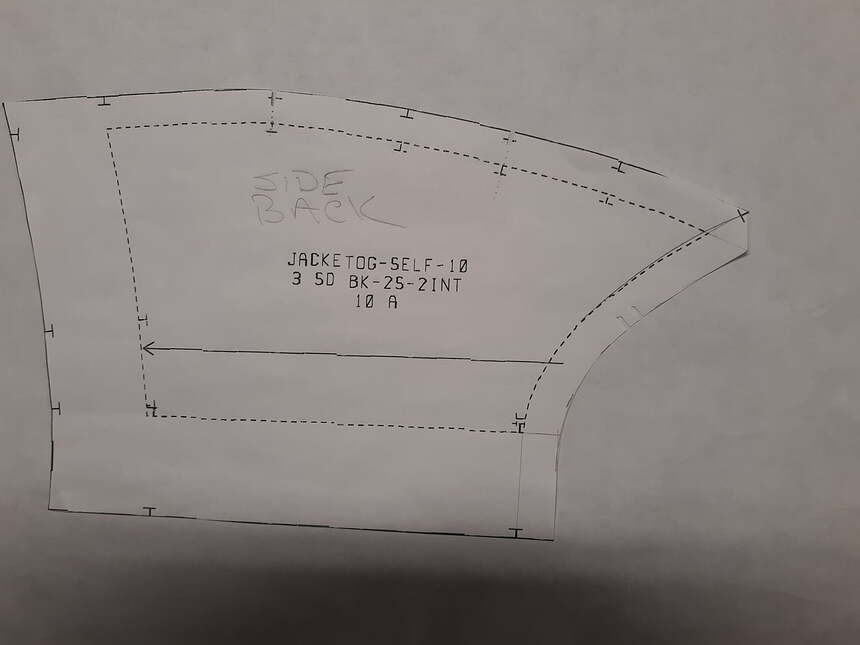

The patterns we received were digitized in a company in New York City. Here’s the Side Back piece… And just as a note - it’s a good idea to clearly label WHICH piece is which. The label they plotted is rather cryptic so I hand wrote the piece names on each piece.

If you look close you notice the punched notches… everyone should have one of these… a notch punch:

Depending what I was cutting and how many layers I would use 1 of my 2 main cutters. An Eastman straightblade:

Or an Eastman rotory cutter:

I had a cutting table that was 6’ wide by 40’ long where the cutters were powered from a feedrail on the ceiling above. The cables had roller connectors that ran inside the feedrail so the cord moves with the cutter, and stays off the table.

I remember the knitting machine weights from an old knitting machine I had waaayyy back when. You really don’t want to drop one on a toe. ![]()

You people did such beautiful work. I’m still crying at the loss of all that skill, equipment, etc. Especially the older stuff that one just can’t replace.

Thank you very much for sharing. I’ll keep an eye open for the movie in about 5 years when it hits RSA.

Probably the biggest loss in that respect was all the various Cornelli machines and parts we had. We ended up buying all the Cornelli stuff from another company in town that closed up. What sucked is that all the machines were on the basement level, which was more or less intact, but once they condemned and started investigating the fire, we couldn’t recover anything.

This was a pic an ATF investigator asked me about the clock which is leaning on a Cornelli machine that’s still intact.

Well, hopefully, skills are not entirely lost. At least Douglas will bestow a special blessing on us who try to carry on some part of the craft, here in the forum. I just love and thrive for those photos, machines and achievements. (Fantastic wool jacket by the way, I just love those balloon sleeves.)

Yeah… the sleeves were all kinds of fun to figure out the pleating, and how to sew all that bulk. Also there is a crinoline piece in the cap to keep the shape. It was a football shape, folded in half, and then bound on a pleating machine. The pices were the stitched onto the seam allowance of the cap.